Unlocking Precision: A Guide to Rotary Tables and Their Applications

Boost your machining, welding, and assembly capabilities with rotary tables, the versatile tools that enable multi-axis control and precise manipulation of workpieces.

What are Rotary Tables?

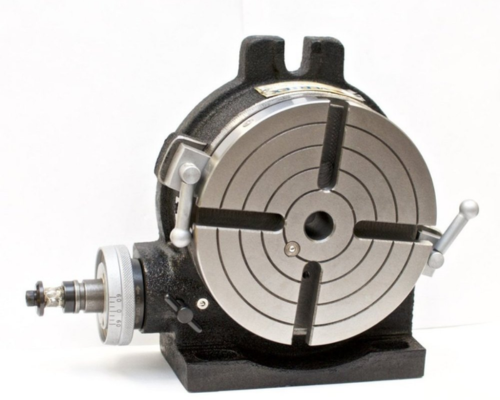

Rotary tables are motorized platforms that rotate along a horizontal or vertical axis, allowing for 360-degree positioning of objects. They come in various types:

➤ Horizontal Rotary Tables: Ideal for flat workpiece machining, drilling, and milling.

➤ Vertical Rotary Tables: Perfect for cylindrical or angled work, like welding, grinding, and assembly.

➤ CNC Rotary Tables: Integrate seamlessly with CNC machines, allowing for automated and complex machining processes.

Unveiling the Benefits:

➤ Enhanced Efficiency: Achieve faster production cycles by processing multiple sides of a workpiece in a single setup.

➤ Improved Accuracy: Achieve superior precision with micro-adjustable indexing and repeatable positioning.

➤ Expanded Capabilities: Unlock complex machining, welding, and assembly tasks previously impossible with fixed workholding.

Find the Right Match:

Rotary tables are available in diverse sizes, capacities, and features to suit your specific needs. Explore options like tilting rotary tables for angled work, high-precision rotary tables for demanding applications, and CNC-compatible rotary tables for automated processes.

Invest in Precision, Invest in Rotary Tables!

Whether you're a seasoned machinist or expanding your workshop, rotary tables offer unparalleled versatility and precision. With this guide, you're well on your way to finding the perfect rotary table to elevate your projects to the next level.

BEARING SALES CORPORATION INDIA

Ph : +918029725059

No-11/2, Lakshmipura Main Road

Abbigere Industrial Area, Chikkabanavara,

Bengaluru, Karnataka 560090